When it comes to large-scale residential or commercial projects, kitchen cabinets play a crucial role in both design and functionality. Choosing the wrong supplier or overlooking key steps in the procurement process can lead to costly mistakes, ranging from delayed deliveries to substandard quality and project downtime. Whether you're managing a multi-unit real estate development or sourcing materials for a hospitality build, avoiding common pitfalls is essential for a smooth and successful project.

Here are the top 10 mistakes professionals often make when buying kitchen cabinets, and how to avoid them.

1. Choosing a Supplier Without Bulk Order Experience

Not every manufacturer can handle large-scale cabinet production. One of the most common bulk kitchen cabinet purchasing mistakes to avoid is assuming that all suppliers offer the same capacity, consistency, and support. A supplier that specializes in retail or one-off orders may not be equipped to meet tight timelines or large-volume consistency.

What to do instead: Look for suppliers with a proven track record in high-volume cabinet production and ask for examples of past projects.

2. Prioritizing Price Over Quality and Reliability

While budget matters, cutting corners on kitchen cabinet purchases often backfires. Low-cost suppliers may use inferior materials, offer limited customization, or fail to meet delivery deadlines. This could result in rework, customer complaints, or non-compliance with building standards.

What to do instead: Consider the total value of the product, including durability, certifications, and service support, not just the upfront cost.

3. Ignoring Customization Capabilities

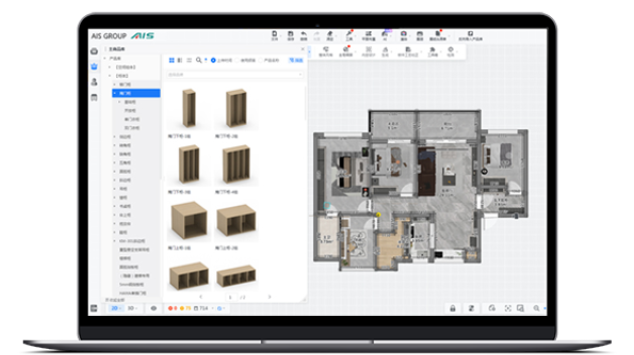

Different projects call for different cabinet configurations. Developers often overlook whether their supplier can support layout-specific designs, custom dimensions, or branding needs. Limited flexibility can result in poor fit or reduced efficiency on-site.

What to do instead: Choose a cabinet manufacturer with strong in-house design teams and flexible production systems.

4. Overlooking Material Quality and Certifications

A cabinet may look good on paper, but what about the materials used? Many sourcing mistakes for developers happen when quality claims aren't verified. Materials that fail to meet local environmental or safety standards can delay approvals or lead to product rejections.

What to do instead: Ask for technical specifications, certifications (e.g., CARB, FSC, E0/E1), and samples before confirming a bulk order.

5. Underestimating Lead Time and Logistics Complexity

Kitchen cabinets are bulky, high-volume items that require careful handling. Relying on vague delivery promises is risky. A lack of planning often leads to delays that impact the construction schedule.

What to do instead: Build realistic timelines, confirm production lead times, and clarify shipment schedules in advance.

6. Not Matching Designs with Site Requirements

Another overlooked detail is how the cabinets align with project-specific layouts. Pre-fabricated options that don't account for architectural or MEP plans can lead to on-site clashes and expensive changes.

What to do instead: Collaborate early with your cabinet supplier to ensure design drawings are aligned with construction documents.

7. Failing to Clarify Installation and After-Sales Support

When kitchen cabinets arrive, the job isn't finished. Without proper installation guidance, even high-quality cabinets can be poorly assembled. Developers often forget to confirm if manuals, video tutorials, or remote support are available.

What to do instead: Choose a supplier that provides clear installation documents, packaging instructions, and after-sales support channels.

8. Working with Suppliers Lacking Export Experience

Sourcing from abroad can be cost-effective, but only if the supplier is experienced in international logistics and compliance. Inexperienced exporters may fumble customs documentation, packaging, or labeling, leading to delays or losses.

What to do instead: Vet your supplier's export experience. Confirm whether they've handled similar markets or project scales before.

9. Ignoring Local Building Codes and Compliance Requirements

Different markets require different standards. Using cabinets that don't comply with fire safety, toxicity, or structural regulations can be a costly mistake.

What to do instead: Request documentation to ensure that the materials and designs meet your country's regulatory framework.

10. Skipping the Sample or Mock-Up Process

In large-scale orders, skipping a prototype or sample installation can be risky. Differences in finishes, dimensions, or functionality may not be visible until it's too late.

What to do instead: Always request samples or even full-scale mock-ups before placing a mass order. It reduces risk and helps align expectations.

FAQ

1. What should I look for in a bulk kitchen cabinet supplier?

Look for a supplier with proven bulk order experience, consistent quality, and strong logistics capabilities. Ask for examples of past high-volume projects and check their customization options.

2. How can I avoid delays when ordering kitchen cabinets for a real estate project?

Plan ahead by confirming production lead times, shipment schedules, and export experience. Work closely with your supplier to align delivery with your construction timeline.

3. Why is customization important for large kitchen cabinet orders?

Every project has unique layouts and dimensions. A manufacturer with flexible design and production capabilities ensures cabinets fit perfectly and meet efficiency requirements on-site.

4. What certifications should high-quality kitchen cabinets have?

Common certifications include CARB, FSC, and E0/E1 standards for material safety and environmental compliance. These ensure your cabinets meet both local regulations and quality benchmarks.

5. How can I ensure the cabinets meet local building codes?

Request official documentation from your supplier to confirm compliance with your country's fire safety, structural, and toxicity regulations before placing an order.

6. Is price the most important factor when buying kitchen cabinets in bulk?

Not always. Focusing solely on the lowest price can lead to poor materials, limited customization, and missed deadlines. Consider overall value, durability, and supplier reliability.

Conclusion

Sourcing kitchen cabinets for a commercial or large residential project requires more than just finding the lowest price. The risks involved, from shipment delays to poor material quality, can derail even the most well-planned developments. By avoiding these common mistakes and partnering with an experienced manufacturer, you can ensure smooth procurement and successful project delivery.

Need reliable sourcing support for your upcoming kitchen cabinet project? Contact our team to get a custom quote or schedule a consultation.